As e-commerce development retains its vertical assent, the net has spawned new territories and new applied sciences, every providing in their very own method, vital financial alternative for vogue designers and retailers. Not the least of those is manufacturing on demand, which is already a keystone in lots of different industries. On this article, compliments of textiles skilled and WhatTheyThink contributor Debbie McKeegan, initially revealed on Pixel to Parcel, the highway to a extra sustainable vogue future, from design to manufacturing, is laid out.

Editor’s Word: This text was initially revealed in Pixel to Parcel.

It takes a extremely organized, multi-disciplined provide chain to fabricate attire for retail in a sustainable format. Once we add in on-demand manufacturing, the strain intensifies. With actually 1000’s of worldwide touchpoints to navigate for every product, it’s a panorama that continues to be burdened with waste and extra.

In distinction, on-demand manufacturing expertise affords new hope for the way forward for sustainable vogue entwined with a optimistic influence for the setting and vital business beneficial properties for the style {industry}. Working collectively, designers, suppliers and producers could make a big distinction, each creatively and commercially, steering the {industry} to a viable future.

To succeed, all stakeholders should digitize their provide chains, making each touchpoint each environment friendly and adaptive plus inherently clear and traceable. And that is the place the expertise race and its implementation start—by connecting the dots from product design to manufacturing: The digital crucial.

As e-commerce development retains its vertical assent, the net has spawned new territories and new applied sciences, every providing in their very own method, vital financial alternative for designers and retailers.

Unpacking the Phygital Product and 3D Simulation

A wasteless product stream stays the holy grail in vogue. Designing digital attire utilizing 3D product simulation has a number of advantages. It enhances creativity and reduces sampling. It’s each reactive and adaptive and delivers merchandise which are finely tuned to buyer demand. However maybe most significantly it removes the requirement for landed inventory and opens the door to shut proximity manufacturing and achievement. It represents the daybreak of the Phygital twin: the Avatar.

Know-how on this sector is advancing at a super-fast tempo. With generative AI nipping on the heels of actuality, seeing is not believing for most of the photographs we now subconsciously soak up. Tank Man is one such instance. The unforgettable picture of 1, single unidentified Chinese language pupil going through off in opposition to 59 tanks in Tiananmen Sq. in 1989—just lately resurfacing as a selfie—was generated anonymously by AI. Product simulation, nonetheless, is a distinct story.

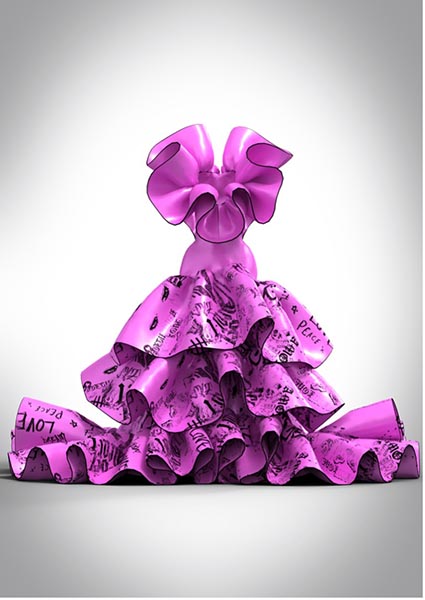

Picture courtesy of PhygitalTwin showcasing a 3D avatar, designed and created for each digital and bodily manufacturing.

A product created and retailed utilizing digital applied sciences have to be a real twin, replicating the ultimate bodily product with 100% accuracy. One other technical mission is simulating the human that showcases the garment, and the garment’s behaviour (drape, stretch, stream) can also be an vital component of the ultimate advertising and marketing story for retail.

Verce: Making Big Strides Between the Bodily and Digital World

Verce is a number one studio creating digital fashions for the Vogue Business and is making vital strikes in direction of high-quality visualizations of hyper-realistic digital people. Their latest undertaking, “Shades of Sense,” exhibits a workflow combining the strengths of industry-leading instruments like CLO3D and Unreal Engine with Verce’s experience in creating digital vogue fashions.

“The hero of the cinematic undertaking is Ava, Verce’s protégé: A digital human that has been fastidiously crafted lately with a hyper-realistic look and an enchanting backstory. In direct interplay with MetaHumans, Ava seems as a beforehand unseen magnificence for the primary time, making her the right ambassador for the digital age of vogue,” Verce states.

Talking on the collaboration, Arndt Johannes, CEO of Verce, mentioned: “We’ve entered the following evolution of digital clothes and vogue basically. The method is to develop into extra human, extra actual. We’re pushing the boundaries of digitalization and opening up unexplored potentialities for content material manufacturing. That may present new, modern alternatives for companies and artists to create one thing outstanding.”

Producing Phygital Vogue for On-Demand Manufacturing

One other firm making headway into digital vogue for retail is the staff at PhygitalTwin. Louise Laing leads a staff of extremely expert technicians that may create digital and bodily clothes for retail utilizing 3D product simulation. This combines using 3D software program and digital manufacturing applied sciences, applied sciences that intention to seamlessly information the product by means of digital design and onto the on-demand manufacturing ground.

The method isn’t seamless but and depends closely on the ability of the designer and the standard of the info enter. Nonetheless, generative AI has a robust hand to play on this sector of attire, and developments are accelerative.

Picture options Blanc de Blanc ballgown created in a collaboration between PhygitalTwin and Vogue Enter.

A Phygital Twin assortment was just lately exhibited at Digital Vogue Week, London, in collaboration with blancdeblanc.com, who commented, “Our London present throughout Digital Vogue Week was an unforgettable expertise! In collaboration with Phygital Twin, we introduced ‘Breeze of Start’ to life. This assortment celebrates the renewal of nature and the rebirth inside every of us. We showcased 10 distinctive designs, blurring the traces between digital and bodily vogue.”

The clothes have been manufactured and printed at Vogue-Enter, a high-tech hub and academy for vogue design. Based mostly within the coronary heart of London, the power operates in partnership Kornit Digital, using their digital textile printing equipment.

Digital Know-how Continues to Unlock the Vogue Provide Chain

Sensible manufacturing utilizing digital applied sciences affords the style {industry} a chance that can not be surpassed. In Poland, Print Logistic (famend pioneers inside the attire manufacturing sector) serves as a formidable portal for on-demand manufacturing. By combining 3D design, product customization, and digital print (utilizing Kornit Digital expertise) they provide a high-tech answer for printed, sewn vogue manufacturing.

Print Logistic spotlights a brand new template for the manufacture of sewn textiles: their enterprise mannequin is adaptive and primed to revolutionize the manufacture and sale of attire clothes and décor merchandise, each on-line and offline. Michal Tracz defined, “We provide a full end-to-end service. From receiving the order, we’re getting ready for manufacturing, printing, slicing, stitching, high quality management, packaging, and dispatch direct to the patron, retail retailer or warehouse.”

As at all times, design is within the element, and when paired with and activated by digital expertise, the way forward for creation and retailing (on-line and off) has no limits. Mining the info from deep inside the provide chain is the important thing to top quality manufacturing. Collaboration amongst all stakeholders is crucial, and as expertise evolves, knowledge should stream seamlessly by means of the worth chain, guaranteeing that the merchandise we simulate are the merchandise we produce and ship.