Digital fabric printing gaining popularity among textile players

Digital cloth printing is gaining a robust foothold within the Yangtze River Delta area, a hub for textile manufacturing and exports in China.

This new mode of printing, which makes use of inkjet expertise to print on cloth or clothes, has the benefit of etching colourful and sophisticated designs on cloth with excessive precision, decreasing hurt to the setting because of its “inexperienced” applied sciences.

Digital cloth printing is suitable for small-scale manufacturing, as it’s less expensive and fewer demanding than display screen printing methods.

Nonetheless, it’s turning into fashionable in large-scale and mass-production cloth printing, as an alternative choice to rotary display screen printing.

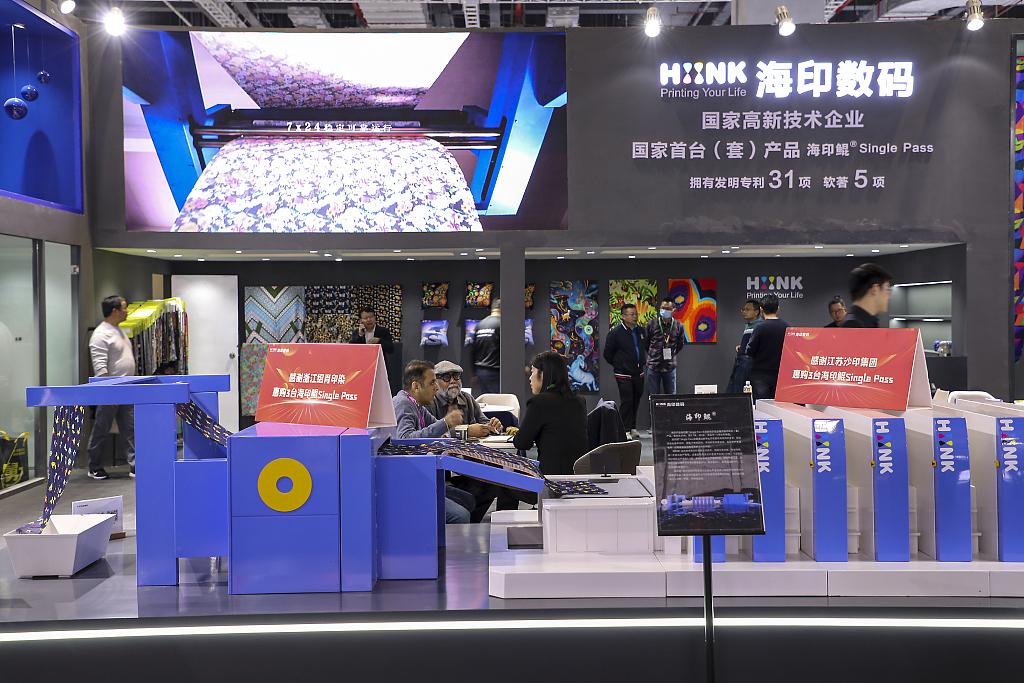

At a manufacturing unit of Hello-ink Digital Expertise Co Ltd in Zhejiang province, a number of massive machines are operating at excessive velocity, effectively printing patterns on materials by means of digital printing expertise.

These machines belong to the “KUN” collection of single-pass digital printing tools, which was first produced by the corporate.

Based in 2016, Hello-ink Digital Expertise is situated in Shaoxing, Zhejiang, which is named the “World Material Metropolis”.

The corporate first produced the “KUN” collection of single-pass digital printing tools in 2019, reforming the normal printing expertise and rising the competitiveness of China”s digital printing expertise within the worldwide market.

China is the world’s largest textile processing and exporting nation, and the Yangtze River Delta space is its hub for each manufacturing and exports.

Earlier, conventional printing and dyeing expertise — which concerned the expensive course of of constructing the display screen and paste — used to result in extreme wastage that harmed the setting.

After the arrival of digital printing applied sciences, multipass printing was broadly utilized. Nevertheless, its each day output might solely attain 600 to three,000 meters per set, a lot smaller than that of conventional machines, which might produce 20,000-60,000 meters per set.

In 2014, Track Shuiyou, founding father of Hello-ink Digital Expertise, proposed a digital printing platform that had extra benefits by way of each day output and printing prices than conventional printing methods.

After plenty of experiments, the “KUN” collection of single-pass digital printing tools was developed, overcoming earlier disadvantages.

The “KUN” single-pass digital printing machine’s velocity is 80 meters per minute and its each day output hits 60,000-100,000 meters per set, which is 1.5 instances that of a conventional rotary display screen printing machine, 5 instances that of a flat display screen printing machine, and 1.5-2 instances that of comparable foreign-made merchandise.

Moreover, the machine additionally options larger printing high quality, with a bodily accuracy of as much as 1200 dpiX2400 dpi, which is 4 instances that of the frequent multipass machine available in the market.

Because it doesn’t contain making the display screen and paste, the printing price is vastly decreased, making it efficient over conventional printing in mass manufacturing.

The only-pass digital printing machine has the potential to utterly exchange conventional printing machines, inflicting much less waste and air pollution.

Based on a third-party testing report, the “KUN” single-pass tools can cut back electrical energy consumption by 52.02 p.c, water by 46.66 p.c, steam by 51.39 p.c, and carbon dioxide emissions by 51.44 p.c throughout the printing course of, in contrast with conventional printing strategies.

At current, a complete of 21 units of “KUN” single-pass machines have been utilized in China, accounting for greater than 70 p.c of all single-pass machines within the nation.

In 2023, the corporate achieved a income of 140 million yuan ($19.63 million).

The emergence of the “KUN” single-pass digital printing tools has enabled the textile printing and garment trade to reverse the sooner mannequin of basing gross sales on manufacturing, serving to to resolve the issue of overstocking and useful resource wastage, thereby realizing environmentally pleasant and sustainable improvement of the trade.

With this, China’s textile trade has entered a brand new period in three new facets: science and expertise, trend, and inexperienced processes.

As a key hyperlink within the textile trade chain, printing and dyeing is a vital course of to reinforce the added worth of textiles.

In recent times, China has issued a collection of business insurance policies to encourage clever manufacturing tools and inexperienced printing and dyeing, thus supporting the appliance of digital printing expertise within the textile trade.

Track mentioned that along with the present “KUN” single-pass machine for cloth printing, the corporate is engaged on new product traces and exploring new utility areas, together with printing tools for large materials in residence textiles and for ebook printing.

“We at the moment are actively looking for to discover additional worldwide markets, akin to India, Pakistan and Southeast Asian international locations, with extra Chinese language textile producers rising energetic in looking for to reinforce their provide chain overseas,” Track mentioned.

mazhenhuan@chinadaily.com.cn